CREATIVITY & TEXTILE INNOVATION

QUALITY

GREEN LAB was born in 2020 as modern division for Research & Development activities. Deeply rooted in the family company Cossiri, born in Florence at the end of ‘800, a leader in garment dyeing and denim treatments from four generations, guarantees reliability and a consolidated experience, 100% Made in Italy.

SUSTAINABILITY

Since the early 1990s we have been presenting Eco-Friendly collections, contributing to bring new technologies into this field like O-zone and Laser.

Our goal has always been to stop the use of hazardous chemicals, reduce the ammount of water and energy and implement new green technologies.

INNOVATION

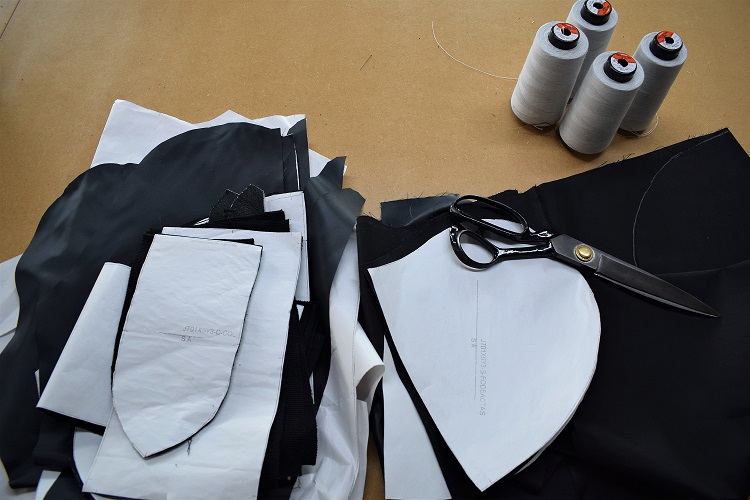

Today GREEN LAB continues to grow and to increase its structure by providing a full package of services: from the construction of pattern, to the steps of cutting and sewing, also washing, dyeing and innovative treatments related to finishing, until the quality control, so finished product.

FULL PACKAGE

GREEN LAB is one of the few companies in Italy to offer a “Full Package”, integrating all the steps of a typical fashion and apparel supply chain into a single company.

This process of verticalization allows for greater traceability and quality control of the product and the possibility of reduce production and delivery times.

A team of experts realizes the ideas of the client, interacting with him from the first step of tests and samples to the final step of production.

One place but thousand layers

For each request an ad hoc solution.

Research of fabrics and trims, pattern construction, cutting and sewing, finishing, quality control.

Where ideas come true

To everyone his total look: outerwear, top, trousers, accessories.

Specialized in casualwear, in particular denim and jersey garments, but also sportwear, like nylon e neoprene garments, up to luxuyrwear with jaquard or paillettes fabric.

From one fabric can born an infinite number of variations

From a denim, so many look.

From a white, so many colours.

Innovation and tradition

Innovative machinery such as laser, ozone machine, E-flow nebulizer machine, to reduce the use of water, energy and chemical products.

Handcraft: scratches and spray, leather and plaster effects.

Prints and embroidery.

GREEN POWER OF DENIM

« we strongly believe that now clothing can and must be produced through sustainable and environmentally friendly systems.»

IT’S TIME FOR A FASHION REVOLUTION

AND WE ARE MAKING THIS REVOLUTION

The key word of GREEN LAB has always been sustainability: respect for the environment and work ethics.

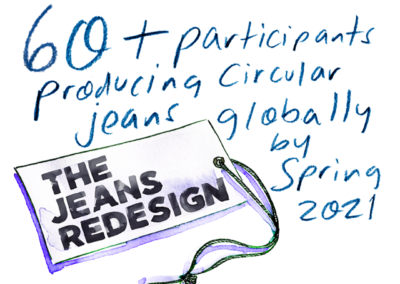

GREEN LAB is one of the sixty leading brands, manufacturers, and fabric mills using the

@ellenmacarthurfoundation’s Jeans Redesign Guidelines to produce circular jeans

that will be available on the market by May 2021

Quote from Francois, MFC lead: “The Jeans Redesign project demonstrates that by working

together we can create jeans that last longer, that can be remade into new jeans at the end

of their use, and are made in ways which are better for the environment and the people that

make them. We’re excited to be working with GREEN LAB on this journey towards a

thriving fashion industry that works in the long term.”

Join our journey to Make Fashion Circular

#JeansRedesign #MakeFashionCircular #circulareconomy

Less water

New machines based on innovative E-flow nebulizer technologies allow enormous savings in water and chemicals.

Recycle of waste water.

Less energy

Use of renewable energy sources.

New cogeneration plant.

Less chemicals

Use of latest ZDHC complies chemicals ecological certified

Thanks to innovative technologies like laser and ozono we can achieve vintage look avoiding any chemical product.

Higg

Developed by the Sustainable Apparel Coalition (SAC), the Higg Index is the leading assessment to measure social and environmental sustainability performance.

GREEN LAB use Higg Index to measure and grow its sustainability practice

x info click Higg Co

Jeans Redesign

Green Lab excited to announce our participation in @circulareconomy’s Jeans Redesign project.

Alongside 50+ other brands we will be transforming the way we produce jeans, tackling waste, pollution, and harmful practices.

x info click Ellen MacArthur foundation the jeans redesign #makefashioncircular

ZDHC

Green Lab implements the ZDHC Foundation’s Roadmap to Zero Program as a chemical management guideline to eliminate the discharge of hazardous chemicals listed in ZDHC Manufacturing Restricted Substance List

X info click ZDHC input

EIM

We face challenges, we reach goals … by measuring results.

EIM, the first Environmental Impact Measuring software specifically for the garment finishing industry.

GREEN LAB use EIM Are you green enough…? Check it now! Come to us.

x info click EIM

ANOTHER POINT OF VIEW

Research as added value, contamination of ideas and styles that comes from an approach to work focused on sharing and the exchange of know-how.

A 360 ° research that mixes creativity and style with the study of innovative and eco-friendly techniques.

A place of ideas and experimentation

Stylistic research focused on new trends from all over the fashion world.

Study of new pattern, research of the right fabric, updates concerning Eco-friendly finishing and products, new technologies and techniques of application.

Two collections every year to introduce all these news.

A showroom to get inspired.

Discover our green innovative technologies

- SMART FOAM: New and esclusive patented eco process, create in collaboration with GARMON CHEMICALS and MACTEC. For info click me

- BIOENZYMES: Modern bioenzymes allow to realize numeorus chemical processes commonly used in the textile industry, such desizing, stonewashing, biopolishing, bleaching and preparation of fibers, oxidation dyes, degreasing …, replacing the use of much more polluting and harmful chemicals for the environment

- ECO-STONE: The most advanced research offers us Eco-Stone way, innovative and sustainable technologies, materials and chemicals: synthetic stone (recyclable clay or porcelain base), panels with innovative abrasive substrate to be installed on the drums of industrial washing machines, mixtures of specific enzymes and active agents that degrade the superficial part of the indigo dye

- ECO- BLEACH: the low-impact bleaching systems are oxidizing agents with an organic acid base, completely biodegradable, free of manganese compounds, heavy metals and halogen derivatives (AOX), therefore free from persistent chemical substances. using low impact oxidants we can definitively replace the widely used potassium permanganate (highly harmful especially for aquifer fauna), hypochlorite and consequently their neutralizations generally made with hazardous chemicals

- OZONE WASH

ozone is a natural gas made of three oxygen molecules (O3). In higher concentration it has a strong oxidizing effect. Ozone replaces chemicals like bleaching agents and other chemical whiteners. Its application process requires no or very little water. It also safes a lot of energy compared with conventional bleaching processes. After it is used in special washing machine it can be converted back to oxygen and then being released climate neutral to the atmosphere again - LASER TREATMENT

the laser techonology impacts the indigo denim dye molecule at very high speed and frequency. The software programming the type of marking and allows us to obtain decorative elements, degradations, whitening and fading effects, breakages and other effects that replace several conventional processes that in past generate an high chemical impact and require manual intensive operations strenuous for the workers and dangerous for human health. - JET SYSTEM

Using Jet System Technology that pump in the washing machine a solution in a continous recycled system, we are able to realize dyeng and finishing application saving around 70% of water, consequently reduction of chemicals and energy request. - CLOUD APPLICATION

Appliyng latest generation chemicals through nebulization system we achieve high quality performance, optimize distribution and egualization saving up to 90% of water, reducing chemical impact because there is no discharge of products in waste water.

A physical test laboratory

Focused and specific tests can guarantee products of excellent quality and durability over time.

A GREEN LAB archive

Over twenty years of test, experience and tradition contained in an archive.

A vintage closet

Original garments from the 50’s to get some ideas and create authentic look or glam revisitations.

LET’S KEEP IN TOUCH

GREEN LAB s.r.l.

via Bore Tesino n.16

Grottammare (AP) ITALY

Tel +39 0735 735284

VAT ID- P.IVA IT 02407660444

codice destinatario 7HE8RN5